#servo and stepper motor

Explore tagged Tumblr posts

Text

Find top-quality stepper servo motors from a reliable supplier. Our range ensures precision and reliability for your automation needs. Stepper Servo Motor Supplier, stepper servo motor, servo motor and stepper motor, servo and stepper motor, servo motor step motor, stepper motor systems, stepper servo motor suppliers, stepper servo motor suppliers in gujarat, stepper servo motor suppliers in india Contact us for superior motor solutions. Explore our range of high-quality motors designed for precision and efficiency For More Info:- https://www.rbautomate.com/stepper-servo-motor.html

#Stepper Servo Motor Supplier#stepper servo motor#servo motor and stepper motor#servo and stepper motor#servo motor step motor#stepper motor systems#stepper servo motor suppliers#stepper servo motor suppliers in gujarat#stepper servo motor suppliers in india

0 notes

Text

A Comprehensible Guide to Servo Motor Sizing

Discover the importance of proper servo motor sizing for optimal motion control performance. Learn how to calculate torque, inertia, and select the right motor to reduce energy costs, improve efficiency, and prevent oversizing.

#servo motor#stepper motor#sizing#torque#inertia#performance profile#speed profile#selection#motion control#motion controller

0 notes

Text

Perbedaan Motor Stepper dengan Servo Motor untuk Mesin CNC dan Robotika

Dalam dunia industri khususnya untuk mesin otomasi, CNC dan Robotika memilih motor penggerak harus mempertimbangkan banyak hal. Baik itu dari sisi akurasi, biaya, dan efisiensi. Motor stepper dan servo keduanya merupakan pilihan populer untuk berbagai aplikasi di industri seperti robotika, otomasi, dan manufaktur. Motor-motor ini bekerja sangat berbeda dan menawarkan kelebihan dan kekurangan yang…

0 notes

Text

Schneider Electric Bangladesh Supplier

Schneider Electric Bangladesh Supplier in Bangladesh to empower everyone to make the most of your strengths and resources, bridging progress and creating sustainability for all. They call it “Life is On”. They aim to be your digital partner for sustainability and efficiency. They drive digital transformation by integrating world-leading process and energy technologies, cloud-connected products,…

View On WordPress

#AC Conductor#DC Conductor#Electrical Conductor#Life is On#Power Conductor#Schneider AC Conductor#Schneider DC Conductor#Schneider Electric#Schneider Electric Bangladesh#Schneider Electric Product Supplier#Schneider Electrical Conductor#Schneider Power Conductor#Schneider Servo Drive#Schneider Servo Motor#Schneider Stepper Motor#Servo Drive#Servo Motor#Stepper Motor

0 notes

Text

Talerzowość sekwencji

y = [[(button)], [(potentiometer)], [(LED)]]; table_of_contents;

x = [(voltage]), [(Ohm), (resistance)]; table_of_proof;

//

y = [(button), (potentiometer), [(LED)]; table_of_semimassels;

x = [(voltage]), [(Ohm), (resistance)] table_of_semiproofs;

// { resistantio_tool = potentiometer(potentio_L, potentio_M, potentio_L) +

[radiato_tool]

(resistantio_tool)

5V -> LED -> potentio_L [potentio_tool] + (potentiometer)

}

{{}} optimizer tool of affective dogma, lol?

///// Test-Case Rezultado. Kolizja sekwencji. + stepper motor *A* serwomechanism;;

Arduino vs bateria

Rozszczelnienie sekwencjonometrualne

^^ Zadanie: Układ oraz kod składający się z Potencjometru, przycisku i diody. Dioda zapala się z wartością zadaną na potencjometrze po wciśnięciu przycisku.

{{{}}} sektor "upper" ; sektor "lower"

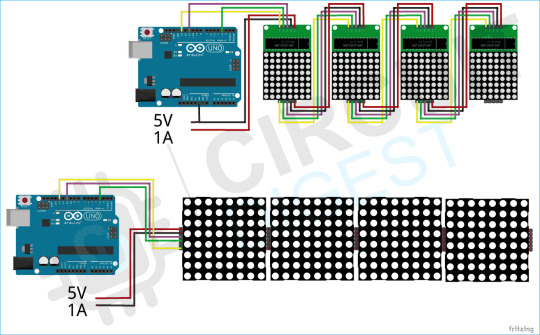

konieczność zastosowań macierzy przy skrzyżowaniach [*których*]

Kolejność podłączeń czy sekwencji.

Konieczność prądu i konieczność uziemienia{ a stechiometria kolimatyczna quote un quote.

Transformacja Fermata (?) : "chodzi o całkowanie przestępne", tj. subweniencyjny tor kolima(torowy).

Słup syntezy i diegezy ciało-czucia-obrazu.

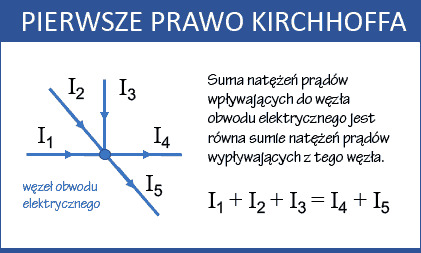

} co z: Prawo Kirchhoffa

vv Zadanie. Wykorzystując potencjometr oraz mapowanie wartości stwórz.... {obrotem serwomechanizmu...} >Incredible Hillar-Jofo<

>Grand Densor{3}< [rzędonumeracja (układu_całkowe)]

i.e = "stechiometry_radiance" possible tools: {[double-check (cathode, anode) OR ((cathode), (anode));

potentiometer -> resistor -> [button_U_R(red)] -> {X *OR* z/y *OR* xyz} -> [button_L_R]

2 notes

·

View notes

Text

We provide a reliable, cost effective and efficient service to various industries throughout the UK and indeed worldwide. Our key areas of expertise are repairing, variable speed drives including; Frequency Inverters, Spindle, Servo, Stepper; HMI’s, Power Supplies, Programmable Logic Controller’s (PLC’s), Printed Circuit Boards (PCB’s), Servo Motors, Encoders and many other types of industrial equipment. Occasionally we use our worldwide network of suppliers to effect a repair.

#electronic restoration services#circuit board repair#printed circuit board repair#electronics repairs#pcb repair

2 notes

·

View notes

Text

Happy Holidays everyone, here's one more small update for the year!

Weld tool

This is a new script mod tool that allows parts to be attached to one another, without them needing to be properly aligned together.

They can even be unfrozen.

Jointed attachments can be created, including rotary, slider, or any other type.

Note that the attachment locations are still derived from the part's alignment grids, so an attachment can't be created at an arbitrary position or orientation. This doesn't make much difference for fixed attachments, but it does limit the possible locations of jointed attachments.

Also note that some part behaviours may be expecting only one attachment of a certain type, and creating extra attachments with the weld tool may result in unexpected behaviour.

This tool is really intended for advanced builders who want to circumvent the usual grid based limitations, it's not intended to replace the standard building system.

Lua scripting

For the modders out there, there are some additions to the Lua scripting API. From a Lua script it's now possible to get and modify part behaviour tweakables, create and delete part attachments, and even apply physics forces to parts. I look forward to seeing what you can come up with using this stuff!

There are a few other improvements and additions too, as always, check out the release notes for details.

Thanks to you all for your support this year, for playing the game, and for sharing your amazing creations!

Release notes:-

Lua scripting changes and new features:-

Added new ITweakables interface implemented by part behaviour to provide access to its tweakables.

Added methods to IAttachmentOperations to create, replace, and delete part attachments.

Added FixedUpdate entry function, called on Lua scripts once per simulation time step.

Exposed fixed delta time value.

Added new IPhysical interface implemented by part descriptor, with a method for applying a force to a part.

Added TargetedPosition property to ITargeter interface.

New script mods:-

ServoTool - Sets a servo / stepper motor's trim angle from its current angle.

WeldTool - For attaching one part to any other, without them needing to be aligned together, or even frozen!

PhysicsExample - A simple demonstration of applying a force to a part.

New 2.5x9 truck wheel (rim designed by Nate).

Implemented joint force / torque debug visualisation, and added options to ConstructionDebug script mod to enable it.

Added dropdown menu to part behaviour UIs, as an alternative way to choose a joystick axis to bind.

Added toggle to video options for disabling chromatic aberration, independent of vignette.

Bug fixes.

2 notes

·

View notes

Text

Capstone #6: Solid

<-<- FIRST || <- PREV || NEXT ->

CAD is nearly done, and the design is 95% there. There's still some improvements to be made. Big 'ol hand to our CAD team especially for bringing this to life. Lets explore under the cut

There's 2 main parts of this thing. The main body has the fans and wheels. The gantry on top does all the doodling. Let's pop the top off.

The cover and walls are purely aesthetic and keeps the dust out. Originally the cover is held on using snap buttons, but that's been changed to the tiniest magnets pocket change can buy. The base plate is made from thin wood, or we've been exploring carbon fiber (but that's proven to be mad expensive for basically no gain. Like 400+$ expensive).

The wheels are servos, the fans sit side by side and run off wall outlet power. (Try making these drone motors that normally run off batteries, and make them run off a wall outlet. Sounds easy right? Good luck. It's been a time doing it. They eat something like 12-16v at 40-60+ amps... *each*). It's got tiny nubs on the bottom to stabilize it, because with only 2 wheels, it's going to want to rock side to side. It'll have some distance sensors on the sides to find where it is on the wall, and an accelerometer to find how it's tilted. I'm personally a little worried the vibrations from the fans will make the accelerometer unreliable, but we'll find out about that later. The whole thing will be controlled by an Arduino Mega.

Smooving over to the gantry, both axis will be on rails purchased from Igus. The rails are made from hard anodized aluminum, while the carriages are made from diecast zinc and some slippery bearing plastic. It's then pulled around by timing belts and steppers. We modified both axis a tad by reducing the rail size to the smallest ones Igus offers, and giving the horizontal axis 2 rails for more stability (The bearing situation on the timing belts were improved too)

The printer head uses an electro-magnet to pull the pen down. There are guide pins with springs to, well, guide and spring return the head. There are also stop screws that set the maximum engagement and disengagement. (The travel distance is kinda exaggerated here tho. The actual travel distance will be as little as possible. Like 3-4mm)

All in all, the bot body is something like 300 x 500mm, 60mm thick (+ 55mm for the fan tails), with a print area of 150 x 150mm. We've tried to cut as much weight as possible, and are looking at about 1.2kg or a little lighter than a small toaster

As a bonus pic, here's an early concept. This one uses a lead screw for the X, and a shaft and timing belt for the Y. If you're wondering what stops the axis from pivoting, it would have been some gibs located behind both axis. Commonly used on dovetails, a gib is when you intentionally design in a large gap between your mating surfaces, and shove a thin plate in there with setscrews to take up the slack. Look at the ways of basically any milling machine or lathe, and chances are you'll see one!

2 notes

·

View notes

Text

Essential Electronic Items for IoT and Electronics Enthusiasts

Are you diving into the world of Internet of Things (IoT) and electronics? Whether you are a seasoned engineer or simply beginning out, having a stable list of essential components is key to bringing your initiatives to existence. Here’s a curated list of electronic objects that each maker and tech enthusiast ought to have of their toolkit:

1. Microcontrollers

Arduino Uno: Great for novices and versatile for diverse projects.

Raspberry Pi: Ideal for more complex duties and going for walks complete operating structures.

ESP8266/ESP32: Perfect for wireless communication and IoT projects.

2. Sensors

DHT22: For temperature and humidity readings.

PIR Sensor: Useful for movement detection.

Ultrasonic Distance Sensor: Measures distances with high accuracy.

3. Actuators

Servo Motors: For unique manage in robotics and mechanical structures.

Stepper Motors: Ideal for applications requiring particular movement.

Solenoids: Good for growing mechanical actions and locks.

4. Displays

LCD Display: Useful for showing records and debugging.

OLED Display: Compact and clean for exact photographs and texts.

5. Connectivity Modules

Bluetooth Module (HC-05/HC-06): For short-range wi-fi communication.

Wi-Fi Module (ESP8266): Connects gadgets to the internet.

GSM Module: Enables verbal exchange over mobile networks.

6. Power Supplies

Battery Packs: Various types for transportable electricity.

Voltage Regulators: Ensure solid voltage ranges in your circuits.

Power Banks: Handy for charging and powering devices on the move.

7. Prototyping Tools

Breadboards: Essential for prototyping with out soldering.

Jumper Wires: For making connections on breadboards.

Soldering Kit: For everlasting connections and circuit meeting.

eight. Additional Components

Resistors, Capacitors, and Diodes: Fundamental for circuit design and stability.

Transistors: Key for switching and amplification tasks.

Connectors and Switches: For interfacing and controlling circuits.

By preserving these objects handy, you'll be nicely-prepared to address a huge range of IoT and electronics projects. Whether you're constructing smart domestic devices, wearable tech, or computerized structures, having the right additives can make all the difference.

#IoT#Electronics#Arduino#RaspberryPi#ESP32#Sensors#Actuators#Displays#ConnectivityModules#PowerSupplies#Prototyping#Tech#DIY#Makers#Engineering#ElectronicComponents#TechProjects

2 notes

·

View notes

Text

Enhancing Industrial Efficiency: The Role of Motors, Adapters & Circuit Breakers

In the age of Industry 4.0, automation is no longer just about moving parts—it’s about intelligent power management, secure connectivity, and system safety. At Dropship Automation Solutions, we supply the essential components that support high-performance industrial systems and resilient infrastructures.

In this blog, we explore three foundational elements of automation hardware: electric motors, industrial adapters, and circuit breakers—each playing a vital role in energy transfer, system compatibility, and operational safety.

1. Motors: Driving Industrial Motion

What Motors Do

Electric motors convert electrical energy into mechanical motion, making them fundamental in powering conveyor belts, pumps, fans, and more. Their reliability and precision keep operations running smoothly across countless industries.

Types & Applications

Types: AC motors, DC motors, servo motors, stepper motors

Applications: Conveyor systems, HVAC units, manufacturing robots, elevators

Benefits: High efficiency, consistent torque, reduced manual labor

Why Motors Matter

Motors are the force behind physical movement in automated systems. With high energy efficiency and precise control, modern motors minimize downtime and optimize mechanical output.

2. Adapters: Connecting Systems Seamlessly

What Adapters Do

Adapters serve as connectors that allow two otherwise incompatible devices or systems to work together. In industrial settings, they enable cross-device compatibility for data, power, or signal transmission.

Common Adapter Types & Uses

Types: Electrical plug adapters, signal adapters, communication protocol converters

Applications: Sensor integration, PLC expansion, international power conversion

Benefits: Device compatibility, simplified upgrades, reduced wiring complexity

Why Adapters Matter

Industrial adapters bridge gaps between old and new technologies, allowing systems to scale without costly replacements. They’re key to maintaining flexible and future-proof automation architectures.

3. Circuit Breakers: Safeguarding Electrical Systems

What Circuit Breakers Do

Circuit breakers protect electrical circuits from overloads or short circuits by interrupting power flow when abnormal conditions are detected. They ensure both equipment and personnel safety.

Types & Use Cases

Types: Miniature circuit breakers (MCB), molded case circuit breakers (MCCB), ground fault circuit interrupters (GFCI)

Applications: Control panels, power distribution, renewable energy systems

Benefits: Overcurrent protection, system isolation, fire prevention

Why Circuit Breakers Matter

Without circuit breakers, electrical faults could lead to equipment damage, fires, or system-wide failures. These devices serve as first-line defenders, ensuring your facility operates within safe power limits.

Building a Safer, Smarter Industry

Imagine an automated facility where:

Motors drive production lines with precision,

Adapters ensure seamless system connectivity,

Circuit breakers protect everything from faults and overloads.

This combination supports efficiency, safety, and adaptability—all key ingredients in modern industrial success.

Conclusion: Power Your Automation with Confidence

Smarter factories rely on trusted components for performance, safety, and scalability. At Dropship Automation Solutions, we provide robust motors, versatile adapters, and reliable circuit breakers to help build your next-gen industrial environment.

Empower your automation strategy—today.

📞 Contact: +1 (234) 288-1755 📧 Email: [email protected] 📍 Location: 1440 W. Taylor St #2555, Chicago, IL 60607

0 notes

Text

Q: Which is the best cutting plotter machine in India for sticker and logo cutting? A: ARC Sign FCG350 and FSG350 from Ambition Gifts offer precision, high-speed cutting with smart touchscreen panels, built-in cameras, and servo/stepper motor options. Ideal for professional businesses looking for quality results. www.ambitiongifts.com

0 notes

Text

Automation Boom Fuels Growth in Motion Control Drive Market to $8.4 Billion by 2031

The global motion control drive market encompassing servo drives, stepper drives, and variable frequency (VFD) drives was valued at US$ 4.9 billion in 2022. Driven by the surge in automation, robotics, and precision motor control requirements, the market is forecast to expand at a compound annual growth rate (CAGR) of 6.2% from 2023 through 2031, reaching US$ 8.4 billion by the end of the forecast period. Motion control drives regulate voltage, current, speed, and position of motors in applications ranging from CNC machining and semiconductor manufacturing to packaging, automotive, and materials handling.

Market Drivers & Trends

Automation & Industry 4.0 Adoption: Increasing deployment of automation across manufacturing verticals is fundamentally reshaping production lines. Motion control drives, which ensure precise and synchronized movements in robotic arms, conveyor systems, and automated assembly lines, are integral to Industry 4.0 ecosystems.

Integration of IoT & AI: Smart factories require drives that can self-diagnose, self-tune, and communicate performance data. The integration of Internet of Things (IoT) connectivity and artificial intelligence (AI) within drives enables predictive maintenance, reduced downtime, and optimized energy usage.

Compact & Modular Designs: Space constraints and the need for flexible machine layouts have spurred demand for compact drive systems. Solutions such as Bosch Rexroth’s ctrlX DRIVE and Rockwell Automation’s ArmorKinetix series offer modular, scalable form factors that simplify installation and support mobile and portable applications.

Energy Efficiency & Sustainability: With global pressures to reduce energy consumption and carbon footprints, manufacturers are adopting high-efficiency drives that minimize losses and recover regenerative energy—key considerations for sectors like automotive, aerospace, and materials handling.

Latest Market Trends

Self‑Tuning Servo Drives: Advanced digital servo drives can now autonomously adjust motor, drive, and feedback parameters to optimize performance. These self‑tuning capabilities reduce the need for manual calibration of control loops and enhance overall system robustness.

Multi‑Axis Synchronization: As multi-axis robots and gantry systems grow more prevalent, drives capable of precise, coordinated control across several axes are in high demand. Enhanced synchronization features enable smoother motion profiles and greater throughput.

Embedded Safety Functions: Functional safety is increasingly embedded into drive platforms, offering integrated safety monitoring, safe torque off (STO), and safe motion functions. This reduces the footprint and complexity of additional safety components in automated machinery.

Cloud‑Based Drive Management: Vendors are launching cloud‑connected platforms for remote configuration, firmware updates, and performance monitoring, enabling centralized management of distributed drive fleets.

Key Players and Industry Leaders

The motion control drive market remains fragmented, with a diverse set of global and regional players competing on innovation, customization, and service:

ABB Ltd.

Siemens AG

Rockwell Automation Inc.

Bosch Rexroth

Mitsubishi Electric Corporation

Schneider Electric SE

Delta Electronics, Inc.

OMRON Corporation

YASKAWA Electric Corporation

Toshiba Corporation

Allied Motion, Inc.

Advanced Micro Controls, Inc.

Fuji Electric Co., Ltd.

Emerson Electric Co.

HIWIN Corporation

Nidec Motor Corporation

These companies remain at the forefront through continuous R&D investment, strategic acquisitions, and partnerships to expand product portfolios and regional footprints.

Unlock crucial data and key findings from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=52011

Recent Developments

August 2023: Kollmorgen expanded its AKD2G servo drive portfolio, introducing higher amperage models with enhanced safety features and SD card backup, plus a graphical display for simplified multi-axis setup.

May 2023: ABB completed the acquisition of Siemens’ low-voltage NEMA motor business, strengthening its portfolio of integrated motor‑and‑drive solutions for North American markets.

2022: WEG acquired Gefran’s Motion Control Business Unit, gaining full ownership of variable frequency drives, DC converters, and specialized servo drives to bolster its automation offerings.

June 2021: Bosch Rexroth launched its ctrlX DRIVE system—a compact, scalable drive platform designed for easy integration into mobile and space-optimized machinery.

August 2023: Rockwell Automation unveiled Allen‑Bradley ArmorKinetix servo drives that mount directly to motors, simplifying machine assembly and improving performance flexibility.

Market Opportunities

Emerging Economies: Rapid industrialization in Southeast Asia, Latin America, and parts of Eastern Europe is driving demand for mid‑range automation solutions—an opportunity for manufacturers to introduce cost‑effective drive systems.

Smart Manufacturing Upgrades: Legacy factories undergoing digital transformation need retrofit‑friendly drive solutions with IoT connectivity and embedded safety, presenting a sizable aftermarket for system integrators.

Sustainable Energy Projects: Renewable energy installations, including solar trackers and wind turbine pitch control systems, require robust drives optimized for harsh environments and long service intervals.

Customized Solutions: Increasingly, end‑users demand turnkey, application‑specific drive packages—bundling drives with built‑in safety, condition monitoring, and domain‑specific software tools.

Future Outlook

Over the next decade, the motion control drive market will continue to evolve along several axes:

Digitalization: Drives will become central nodes in digital value chains, sending real‑time telemetry to cloud‑based analytics platforms for AI‑driven optimization.

Integration: We can expect tighter integration of drives with higher‑level controllers—blurring the lines between PLC, motion controller, and drive in next‑generation architectures.

Safety & Compliance: As regulatory standards evolve, drives will natively support functional safety protocols (e.g., TÜV‑certified safety functions) to simplify machine approvals.

Miniaturization: Advances in power electronics will permit further size reduction, enabling distributed, embedded drive solutions in compact robotics and wearable exoskeletons.

Buy this Premium Research Report and access vital insights and analysis – https://www.transparencymarketresearch.com/checkout.php?rep_id=52011<ype=S

Market Segmentation

By Type: AC Drives, DC Drives

By Product Type: Servo Drives, Stepper Drives, VFD Drives

By Axis: Single‑Axis, Multi‑Axis

By Precision: Very High Precision, High Precision, Standard

By End‑Use: Semiconductor & Electronics, Food & Beverage, Aerospace & Defense, Automotive, Paper & Printing, Pharmaceuticals, Metals & Machinery, Others

Regional Insights

Asia Pacific: Held the largest share in 2022, driven by heavy investments in manufacturing automation and robotics in China, Japan, South Korea, and India. China’s shrinking labor force and rising robotics installations (81,600 units in 2021, up 30%) underpin strong demand.

North America: Growth fueled by automotive electrification, semiconductor fab expansions, and food & beverage upgrades—coupled with strategic investments by ABB and Rockwell.

Europe: Focus on Industry 4.0 and sustainability is driving adoption of energy‑efficient drives, particularly in Germany, Italy, and the U.K.

Latin America & MEA: Emerging manufacturing hubs in Brazil, Mexico, and UAE present opportunities for mid‑tier drive manufacturers.

Why Buy This Report?

Comprehensive Analysis: Detailed market segmentation, quantitative forecasts (US$ Bn & million units), and historical data spanning 2017–2022.

Strategic Insights: In‑depth qualitative analysis, including drivers, restraints, opportunities, key trends, Porter’s Five Forces, value chain, and competitive landscape.

Company Profiles: Thorough profiles of leading players—covering corporate strategy, financials, product portfolios, M&A, and recent developments.

Decision‑Making Support: Actionable recommendations for new market entrants, technology licensors, system integrators, and investors seeking to capitalize on emerging applications and regional growth hotspots.

Multi‑Format Delivery: Available in PDF and Excel formats, facilitating integration with internal reporting and strategic planning processes.

Explore Latest Research Reports by Transparency Market Research: SMT Equipment Market: https://www.transparencymarketresearch.com/smt-equipment-market.html

Motion Control Drive Market: https://www.transparencymarketresearch.com/motion-control-drive-market.html

3D Printing Medical Devices Market: https://www.transparencymarketresearch.com/3d-printing-medical-devices-market.html

Nano Positioning Systems Market: https://www.transparencymarketresearch.com/nano-positioning-systems-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Sticker Labeling Machine Manufacturers: Custom Solutions for Every Industry

In the rapidly moving environment of product packaging, one can never provide enough stress on the need for speed, accuracy, and reliability in labeling. With so many industries involved, including pharmaceutical, food and beverage, cosmetics, and chemicals, sticker labeling machine manufacturers fulfill their end of the demands. With businesses gearing toward automation and compliance, selecting the right sticker labeling machine manufacturer becomes an added strategic decision affecting productivity, quality, and brand reputation.

What is the Role of Sticker Labeling Machine Manufacturer?

Sticker labeling machine manufacturers are engaged in the design and production of machines that ensure the automatic application of self-adhesive labels onto all sorts of containers. The machines are built in such a manner that they can apply labels onto products ranging from tiny vials and ampoules to huge bottles and jars. The main objective remains to accurately apply each label quickly and consistently, with little to no human error, thereby increasing throughput.

Types of Sticker Labeling Machines

The manufacturing companies present an array of sticker labeling machines to meet every packaging requirement:

Automatic Sticker Labeling Machine: These sticker labeling machines are made for high-speed, high-volume operations in which hundreds of containers can be labeled per minute. Such machines find their best use in instances where the demand for efficiency and accuracy are very high.

Bottle Labeling Machine: Being specifically designed for round, flat, oval, and square bottles, these machines can label any bottle smoothly, regardless of its shape or material.

Front and Back Labeling Machines: These systems label both the fronts and backs of containers in just a single pass, allowing for greater productivity of items that require dual labeling.

Wrap-Around Labeling Machine: These machines provide cylindrical bottles with a wrap-around label and are mostly used for beverages and pharmaceuticals.

Custom Labeling Solutions: Custom solutions are offered by the top manufacturers to address any unusual container designs, label sizes, and production requirements.

Learn more, How Sticker Labeling Machines Improve Efficiency in Packaging

Key Features Offered by Leading Manufacturers

The leading sticker labeling machine manufacturers put all advanced technologies in and the user interface depending on the operations:

Label dispenser with microprocessor control: Ensures labels are positioned with precision, hence reducing wastage.

Sensor-equipped systems: These sense the position of bottle and labels for exact application.

Servo and stepper motor drives create smooth and synchronized movement to label consistently even at high speeds.

PLC and touchscreen controls for operators to change settings, observe workings, and diagnose problems.

Adjustment without tools allows fast changeovers from one product to another or from one label size to another, reducing downtime.

Durability: Machines are typically constructed from stainless steel, ensuring durability, and conforming to hygiene standards laid down for food and pharma sectors.

Industries Benefiting from Sticker Labeling Machines

Pharmaceuticals: Exactly labeled to comply with regulatory requirements for traceability of vials, ampoules, and bottles.

Food & Beverage: High-speed bottle labeling machines are used to aid mass production and branding.

Cosmetics & Personal Care: Labeling solutions are customizable to accommodate various packaging designs and materials.

Chemicals & Agrochemicals: The machines are very sturdy to endure harsh conditions and are capable of labeling different containers.

Why Choose a Reputable Sticker Labeling Machine Manufacturer?

Choosing a trusted sticker labeling machine manufacturer guarantees:

Constant Quality: Machines are manufactured to international standards, giving them reliable performance and requiring little maintenance.

Customization: Machines can be customized by manufacturers according to requirements of a particular production, specific container shapes, and specific materials of labels.

After-Sales Support: Comprehensive service, training, and provision of spare parts ensure long-term operational goals.

Cost-Efficiency: By use of advanced automation, further saving on labor cost and increasing output, provides rapid rate of return.

Bottle Labeling Machine: A Fine Look

An indispensable part of the packaging lines of beverage, pharmaceutical, and cosmetic industries, labeling machines treat bottles of all shapes-rounded, flat-sides with different capacities and speeds. PLC control systems and servo-based label dispensers combined with sensor/alignment systems make sure the sticker labels are perfectly placed on bottles even at speeds of 100 bottles/minute.

Manufacturing Trends in Sticker Labeling Machines

Integration with Smart Manufacturing: Modern machines integrate IoT connectivity for real-time monitoring and data analytics.

Sustainability: The focus for manufacturers is towards energy-efficient designs and compatibility with eco-friendly label materials.

Versatility: More and more machines are becoming modular in order to be modified rapidly for new products or new packaging formats.

Conclusion: Aim Technologies-Your Trustworthy Sticker Labeling Machine Maker

Choosing a trustworthy sticker labeling machine manufacturer puts Aim Technologies in a category by itself. They offer a full range of automatic sticker labeling machines and bottle-labeling machines serving pharmaceuticals, food and beverage, and chemical lines. An abiding commitment to innovation, quality, and customer satisfaction ensures that clients receive the latest state of art labeling solution designed to fit their very own requirements. When it comes to sticker labeling machine manufacturers, Aim Technologies is the name a business would want to associate for precision, efficiency, and long-term value.

0 notes

Text

Hey everyone, it's time for another game update!

But first I just wanted to say a big thanks to all of you for playing the game and sharing your creations. It's great to see so many new players joining the community, it really helps motivate me to keep trying to make the game better!

OK, on to the update.

Soap Box Challenge

See how fast you can get down the hill under gravity alone, no motors allowed. This new scenario gives you an idea of the kind of "mini games" possible with Lua scripting, but it still barely scratches the surface really, hopefully we can push the boundaries of this more in the future. Anyway, check it out and let me know what you think.

New Parts

Continuous servo motors, more crown, rack, & worm gear sizes, more "hole & plate" connectors, and round ended beams.

Part Behaviours

Separate servo forward & reverse angles, flip pulley belts, link displays to multiple parts, etc.

Here's a quick look at some of these changes:

youtube

Release notes:-

New Soap Box Challenge scenario.

New parts:-

Small and medium continuous servo motors.

24T and 40T Hi & Lo crown gears.

x3 rack gear.

x1 worm gear.

More "1-Hole Plate" and "2-Hole Plate" resizable connectors.

Rounded and half rounded resizable beams.

Part behaviour improvements:-

Servo motor part behaviour now has separately tweakable forward and reverse angles.

Servo and stepper motor part behaviours now have an "angular speed" data channel.

Pulley part behaviour now has an option to flip belt routing.

Displays can now be linked to multiple other parts.

Motor, battery, and rotor parts can now attach to each other, and to other parts in a more consistent way.

Changed plate on "plate axle" connector part to be circular.

Tweaked material strength of all wheels.

Added buttons to UI screens to open containing folder in Windows Explorer.

Added player "free flight movement mode" setting to allow for moving horizontally rather than along the view direction.

Added settings to the controls options screen for disabling each of the manipulators.

Improved crosshair.

Added Hungarian translations to currently localised strings, thanks to BlueGoldFlag.

Bug fixes.

Upgraded to Unity 2021.3.33.

2 notes

·

View notes

Text

What Key Factors Should You Consider When Choosing an Automation Products Supplier?

Understanding the Role of an Automation Products Supplier

In today’s fast-paced industrial landscape, businesses depend heavily on reliable Automation Products Supplier in Kuwait partners to streamline operations, improve productivity, and maintain a competitive edge. Automation has become essential across sectors such as manufacturing, logistics, healthcare, and more, driven by the need for efficiency, accuracy, and cost control. The right supplier not only provides advanced products but also delivers technical support, customization, and ongoing services that are crucial for long-term success.

Types of Automation Products Available

Automation products cover a wide range of technologies, each serving specific roles in industrial and commercial applications:

Programmable Logic Controllers (PLCs): These are ruggedized computers designed to control manufacturing processes, offering high reliability and ease of programming for tasks like assembly lines and robotic devices.

Human Machine Interfaces (HMIs): HMIs provide intuitive control panels for operators, enabling easy visualization and management of complex systems through touch screens and multi-touch interfaces.

Motion and Drives: Includes servo motors and stepper motors used for precise control of position, speed, and torque in automated systems.

I/O Systems: Inputs and outputs (I/O) connect various sensors and actuators to central controllers, supporting multiple communication protocols for distributed control.

Sensors and Vision Systems: Photoelectric, proximity sensors, and machine vision cameras are used for detecting objects, monitoring production lines, and ensuring quality control.

Accessories and Connectivity: Products such as cordsets, communication cables, and software for programming and troubleshooting are essential for seamless integration and maintenance of automation systems.

Why Supplier Selection Matters

Choosing the right automation products supplier is a strategic decision that impacts every aspect of your operations. Here are key factors to consider:

Product Range and Innovation: Leading suppliers offer a comprehensive portfolio, including the latest advancements in robotics, artificial intelligence, and IoT-based control systems. This ensures your business can adopt new technologies as they emerge.

Reliability and Support: A reputable supplier provides technical support, training, and after-sales services, helping you maximize the value of your investment and minimize downtime.

Customization and Scalability: As industries evolve, the demand for customized and scalable solutions grows. The best suppliers work closely with clients to tailor products that fit unique operational needs.

Global Reach and Local Presence: Top suppliers often have a global footprint with strong local support, ensuring timely delivery and service regardless of location.

Security and Compliance: With increasing digitalization, security is paramount. Suppliers should offer solutions with robust cybersecurity features and comply with relevant industry standards.

Market Trends and Growth Opportunities

The global industrial automation market is expanding rapidly, with a high growth rate projected for the coming years. This growth is driven by rising labor costs, a shortage of skilled workers, and government initiatives promoting automation for efficiency and sustainability. Companies are investing in technologies such as edge computing, 5G, and digital twin systems, which enable real-time monitoring and predictive maintenance for smarter operations.

Conclusion

Selecting the right Automation Products Supplier in Kuwait is critical for any business aiming to thrive in an increasingly automated world. By evaluating suppliers based on product offerings, innovation, support, and security, companies can ensure they are well-equipped to meet current demands and adapt to future challenges. As automation technology continues to evolve, partnering with a knowledgeable and reliable supplier will help your business achieve greater efficiency, productivity, and long-term growth.

Also Read: Rexroth Pumps and Valves Supplier in Kuwait

0 notes

Text

5 Common CNC Router Controller Issues and How to Fix Them

In the world of modern manufacturing, CNC routers are indispensable for achieving precision and efficiency. However, even the most advanced machines are vulnerable to technical glitches—particularly with their controllers. A CNC router controller is essentially the command center that translates software instructions into physical movement. When something goes wrong here, it can bring your entire operation to a halt.

This article dives deep into the five most common CNC router controller issues, how to troubleshoot them effectively, and what you can do to prevent them in the future. Whether you're running a small shop or managing a high-volume production line, these insights will help keep your machine in top shape.

1. Controller Won’t Power On

You hit the switch—and nothing. No lights, no motion, no signs of life.

Why It Happens:

Blown fuses or breakers.

Loose or disconnected power cables.

Malfunctioning power supply unit (PSU).

Incorrect input voltage or surge damage.

How to Fix It:

Check and replace any blown fuses.

Make sure power cords are firmly connected and not frayed.

Test the PSU with a multimeter to verify correct output voltage.

Use a voltage regulator or surge protector to prevent future damage.

Pro Tip: Label your power supply connections clearly during setup. It makes troubleshooting faster and easier.

2. Freezing or Crashing During Jobs

Midway through a cut, your router suddenly locks up. Job ruined, material wasted.

Why It Happens:

Controller overheating due to poor airflow.

Bugs or incompatibility in the firmware/software.

Memory overload from excessive G-code complexity.

EMI (electromagnetic interference) or loose data connections.

How to Fix It:

Keep the controller clean and properly ventilated.

Ensure all software and firmware are updated to stable versions.

Break up large files into smaller toolpaths.

Use shielded cables and ensure proper grounding to eliminate EMI.

Maintenance Hack: Consider using CNC Control Retrofits that come with improved cooling and processing power to reduce these occurrences significantly.

3. Axis Movement Not Working

If your CNC router won’t move along the X, Y, or Z axis, you’re essentially grounded.

Why It Happens:

Stepper driver failure.

Motor or cable disconnects.

Faulty G-code or coordinate settings.

Loose or stripped motor couplings.

How to Fix It:

Double-check driver and motor connections.

Test drivers individually by swapping them between axes.

Inspect and fix any loose mechanical parts.

Review your CAM setup to ensure proper motion commands are being sent.

Upgrade Tip: If your machine frequently suffers from axis issues, consider CNC Control Retrofits that upgrade your stepper systems to more reliable and powerful servo motors.

4. Controller Doesn’t Connect to Computer

You plug in the USB cable and nothing happens—no connection, no control.

Why It Happens:

Outdated or missing drivers.

Cheap or damaged USB cables.

Wrong COM port selected in software.

Firmware and software version mismatch.

How to Fix It:

Install the correct drivers (often CH340 or FTDI).

Replace USB cable with a short, shielded one.

In your control software, manually select the correct COM port.

Verify the firmware on your controller is compatible with your software version.

Pro Note: Avoid USB hubs. Connect directly to your PC's port whenever possible.

5. Spindle Won’t Start or Has Speed Issues

Spindle problems can cause major setbacks—especially when cuts rely on consistent speeds.

Why It Happens:

No PWM or analog control signal.

Misconfigured spindle driver or VFD.

Incorrect G-code spindle commands (e.g., M3, S1000).

Motor overload or faulty wiring.

How to Fix It:

Ensure all spindle control wiring is secure and accurate.

Verify VFD settings align with your spindle motor specs.

Use test commands (M3 S1000, M5) to isolate the problem.

Test spindle motor directly to confirm it’s functional.

Expert Insight: CNC Control Retrofits often include improved spindle control systems, allowing for smoother and more reliable speed regulation across various materials.

Bonus: Preventing CNC Controller Problems

Fixing problems is good. Preventing them is better. Here’s how:

Regular Cleaning: Dust buildup is the silent killer of electronics.

Firmware Updates: Always run the most stable versions—not betas.

Cable Management: Keep power and signal wires separated.

Surge Protection: Always use voltage regulators or UPS systems.

Monthly Checklist: Schedule a 15-minute inspection every month to check connections, clean filters, and back up your machine settings.

Conclusion

CNC routers are amazing tools—but only when the controller is functioning flawlessly. Whether you're dealing with power issues, motion problems, or connectivity failures, the key is understanding what’s going wrong and how to fix it efficiently.

As we've seen, many common problems can be traced back to simple issues like loose wires or outdated software. But if you're constantly struggling with performance or compatibility, it's worth considering CNC Control Retrofits to upgrade aging systems with modern, more reliable hardware.

By applying the strategies in this guide, you'll not only be ready to fix issues quickly, but you'll also be in a strong position to prevent future downtime, maximize efficiency, and get the most out of your CNC investment.

1 note

·

View note